Lithium-rich Mn-based oxide (LRMO) is one of the next-generation cathode materials for lithium-ion batteries (LIBs), which are expected to exceed a high energy density of 550 Wh kg-1.

The redox reaction of anionic oxygen (O2-) is sluggish and unstable, resulting in poor rate capability and cycle performance of LIBs, especially in solid-state batteries.

Recently, a research team led by Prof. Cui Guanglei from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) of the Chinese Academy of Sciences (CAS) has provided new insights into the detection of heterogeneous Li+ Transport dynamics and regulation of anion-oxygen stability of LRMO cathode materials.

LRMO materials have better prospects for solid-state battery applications than commercial cathode materials because of their high specific capacity and low cost. “It is an important premise to solve the key scientific problems of LRMO by clarifying the micromechanism of degradation and developing innovative materials processing technologies,” said Prof. Cui of QIBEBT.

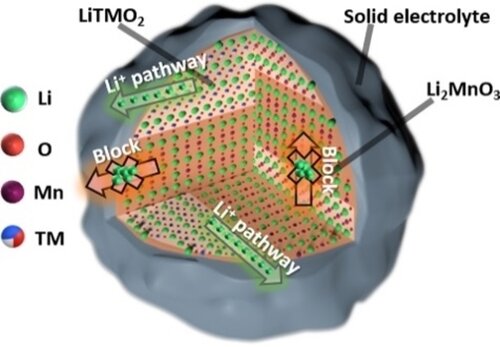

The team observed the heterogeneous Li for the first time+ Transport behavior of LRMO in sulfide solid-state batteries using in situ differential phase-contrast imaging (STEM-DPC) scanning transmission electron microscopy technique. They found that the nanoscale two-phase separation (NCM111 phase and Li2MnO3 phase) in the LRMO was crucial for the Li+ Transport heterogeneity in the bulk phase and at the cathode–solid electrolyte interface, which severely limits the capacity contribution of lithium-rich Li2MnO3.

Their study was published in International edition of Angewandte Chemie.

“We have studied the ‘structure-activity relationship’ between the microstructure Li+ transport kinetics and electrochemical performance of LRMO and clarified the micromechanism of power damping for LRMO cathodes in solid-state batteries,” said Ma Jun, associate professor at QIBEBT. This study further demonstrates the importance of finely optimizing the crystal structure and the Li+ Transport kinetics at the cathode/electrolyte interface.

In another study published in Advanced energy materialsthe researchers proposed a new material preparation technology of seesaw-like non-isothermal sintering (SNS) that stabilizes the lattice oxygen in the bulk phase of LRMO and reduces the generation of transient O2p holes.

Compared with the conventional constant temperature sintering (CTS) technology, the electrochemical performance of the cathode made by SNS technology, such as specific discharge capacity and cycle stability, has been improved.

In addition, the feasibility of the SNS technology was also demonstrated in the cobalt-free, lithium-rich, manganese-based cathode material system (Li1.2Mn0.6no0.2O2).

“This study will provide guidance for stabilizing the anion-oxygen structure and increasing the integral electrochemical properties of LRMO materials,” said Zhang Yuhan, the study’s first author.

“The above works lay a solid foundation for exploiting the LRMO-based solid-state batteries with high energy density and high safety,” said Prof. Cui.

Flexible solid electrolytes for all-solid-state lithium batteries

Bowen Liu et al., Direct Observation of Nanoscale Phase Separation-Induced Heterogeneity of Li Ion Transport in Li‐rich Solid State Battery Cathodes, International edition of Angewandte Chemie (2022). DOI: 10.1002/anie.202209626

Yu‐Han Zhang et al, Stabilization of Lattice Oxygen in Li‐Rich Mn‐Based Oxides by Rocking‐Type Nonisothermal Sintering, Advanced energy materials (2022). DOI: 10.1002/aenm.202202341

Provided by the Chinese Academy of Sciences

Citation: New strategies to accelerate the application of lithium-rich Mn-based cathodes (2022 October 10) retrieved October 11, 2022 from https://phys.org/news/2022-10-strategies-application-lithium-rich- mn-based -cathode.html

This document is protected by copyright. Except for fair trade for the purpose of private study or research, no part may be reproduced without written permission. The content is for informational purposes only.

#strategies #accelerate #application #lithiumrich #Mnbased #cathodes

Leave a Comment