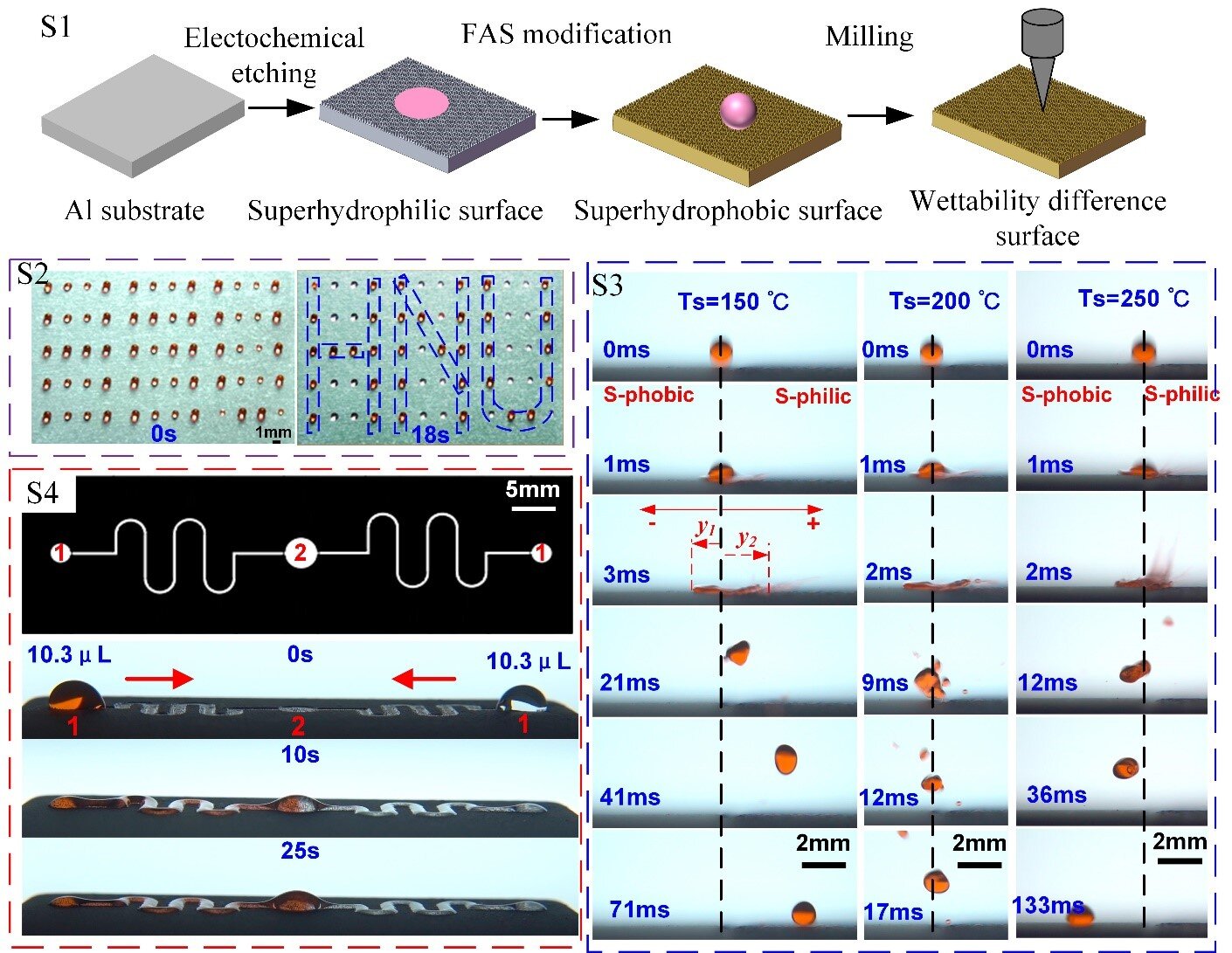

Hunan University research team has proposed a simple and industrially applicable method to fabricate a surface with extreme wettability on an Al-based superhydrophobic surface through a composite process of electrochemical mask etching and micro-milling, and achieves controlled evaporation, directional rebound and transport of droplets on this surface for the first time over a wide temperature range.

The transport platform based on differences in wettability will open up further applications in biochemistry, microfluidic systems, cell culture and energy production and use. This research was published in the Journal International Journal of Extreme Manufacturing.

The evaporation rate of droplets on superhydrophobic surfaces was lower than that of droplets on hydrophilic surfaces. Controlled evaporation of droplets on a hydrophilic micropit dot matrix, circular groove pattern, or other wettability differential pattern can be achieved by controlling the geometry of the hydrophilic pattern.

Directional deflection of droplets with different spacings can be achieved by controlling the magnitude of the substrate wettability difference over a wide temperature range. The droplets rebound toward the more wettable hydrophilic area, the greater the difference in wettability, the greater the speed and distance of impact.

If the substrate temperature is below the Leidenfrost boiling point, the droplet will ricochet towards the hydrophilic region. In contrast, droplets bounce off the junction vertically or move toward the superhydrophobic region due to the thrust created by the vapor layer.

Controlled transport of droplets over a wide temperature range with confluence and split flow using Laplacian pressure gradients on extremely wettable surfaces has been realized. With the temperature gradient drive, a directional and gravity-resistant transport of deionized water, anhydrous ethanol and kerosene with different viscosities can be realized, with the droplet migration speed increasing with the temperature gradient.

By analyzing the phenomenon of droplet motion on wettable surfaces, researchers were able to understand the effect of different wettability surfaces on droplet motion. The researchers found that the size of the hydrophilic area at room temperature affected the evaporation rate and the transport direction of the droplets, which tended to bounce more towards hydrophilic areas. However, at high temperatures, the droplet rebounds toward the superhydrophobic region.

The team investigated a promising method to industrially produce wettability-differentiated surfaces, but the experimental technique they developed can be used for many different applications.

Yao Lu from Queen Mary University of London says: “This is a very valuable and promising achievement and it is just the beginning – we are already trying to use this technique to support the development of bionic functional surface structures that will be used in industries such as e.g such as biochemistry, microfluidic systems and energy production and use.”

Even droplets sometimes take the stairs

Chengsong Shu et al, Preparation of a Surface with Extreme Wettability for Controllable Droplet Manipulation over a Wide Temperature Range, International Journal of Extreme Manufacturing (2022). DOI: 10.1088/2631-7990/ac94bb

Provided by the International Journal of Extreme Manufacturing

Citation: Controlled Bouncing, Evaporation and Transport of Droplets on a Liquid-Repellent Surface (2022 October 24) retrieved October 25, 2022 from https://phys.org/news/2022-10-evaporation-droplets-liquid- repellent surface. html

This document is protected by copyright. Except for fair trade for the purpose of private study or research, no part may be reproduced without written permission. The content is for informational purposes only.

#Controlled #impact #evaporation #transport #droplets #liquidrepellent #surface

Leave a Comment