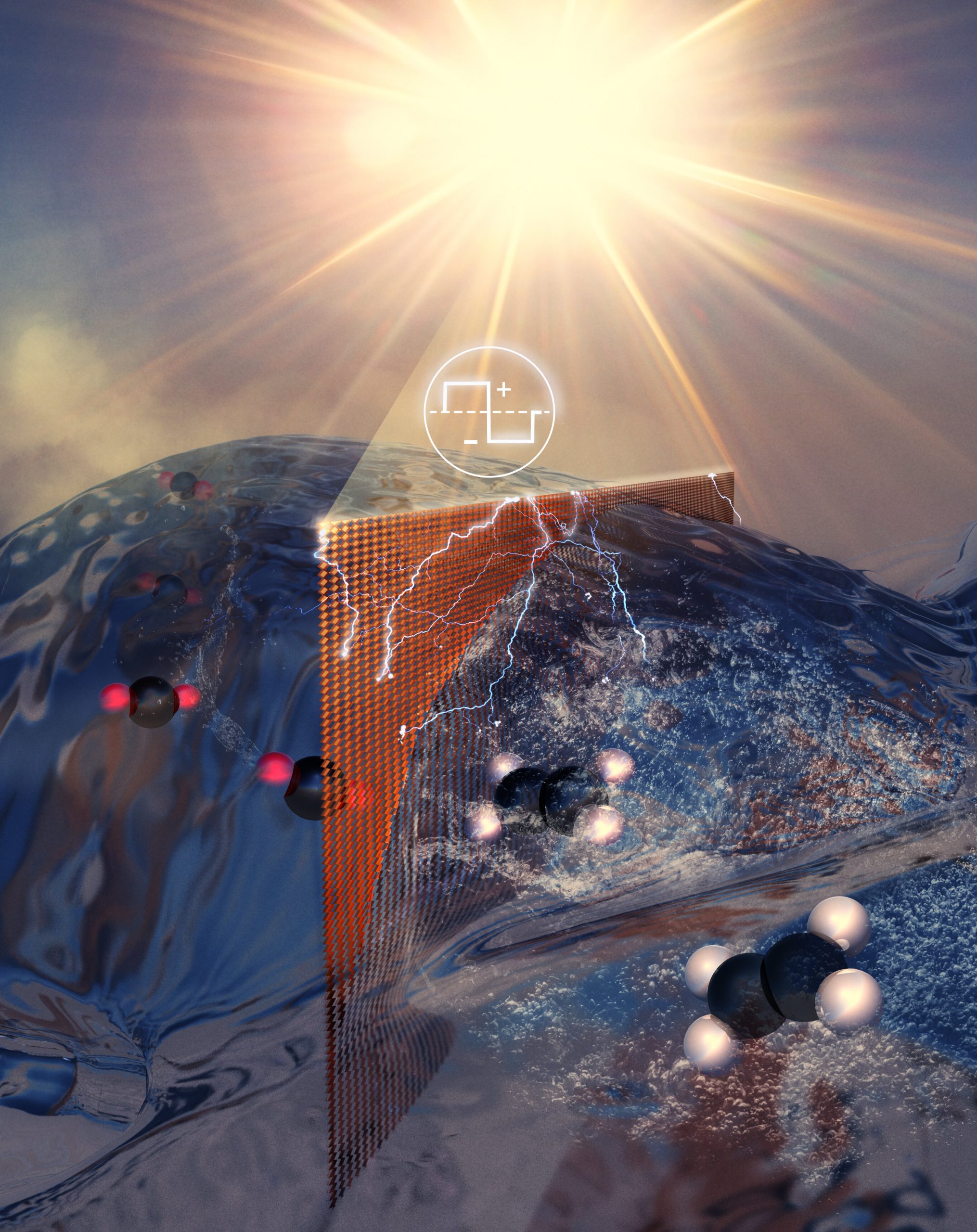

Abstract illustration of atoms streaming through water and an electrified membrane under a radiant sun. Credit: Meenesh Singh

A team of researchers led by Meenesh Singh of the University of Illinois Chicago has discovered a way to convert 100% of the carbon dioxide captured from industrial exhaust into ethylene, a key building block for plastic products.

Your results will be published in Cell Reports Physical Science.

While researchers have been investigating the possibility of converting carbon dioxide into ethylene for more than a decade, the UIC team’s approach is the first to achieve near 100 percent use of carbon dioxide to produce hydrocarbons. Their system uses electrolysis to convert captured carbon dioxide gas into high-purity ethylene, with other carbon-based fuels and oxygen as by-products.

The process can convert up to 6 tons of carbon dioxide into 1 ton of ethylene, with almost all of the captured carbon dioxide being recycled. As the system runs on electricity, the use of renewable energy can make the process carbon negative.

According to Singh, his team’s approach exceeds the net-zero carbon goal of other carbon capture and conversion technologies by actually reducing the industry’s overall carbon emissions. “It’s a net negative,” he said. “For every ton of ethylene produced, you take 6 tons of CO2 from point sources that would otherwise be released into the atmosphere.”

Previous attempts to convert carbon dioxide to ethylene have relied on reactors that produce ethylene within the source’s carbon dioxide emissions stream. In these cases only 10% CO2 Emissions are typically converted to ethylene. The ethylene later has to be separated from the carbon dioxide in an energy-intensive process, often using fossil fuels.

In the UIC approach, an electric current is passed through a cell half filled with captured carbon dioxide and the other half with a water-based solution. An electrified catalyst pulls charged hydrogen atoms from the water molecules into the other half of the membrane-separated unit, where they combine with charged carbon atoms from the carbon dioxide molecules to form ethylene.

Among the chemicals produced worldwide, ethylene ranks third in terms of CO2 emissions, after ammonia and cement. In addition to making plastic products for the packaging, agricultural, and automotive industries, ethylene is used to make chemicals used in antifreeze, medical sterilizers, and vinyl siding for homes.

Ethylene is usually made in a process called steam cracking, which requires tremendous amounts of heat. Cracking produces around 1.5 tons of CO2 emissions per ton of ethylene produced. On average, manufacturers produce around 160 million tons of ethylene every year, resulting in more than 260 million tons of carbon dioxide emissions worldwide.

In addition to ethylene, the UIC scientists were able to use their electrolysis approach to produce other carbon-rich products that are useful for industry. They also achieved very high solar energy conversion efficiencies, converting 10% of the energy from the solar panels directly into carbon products. This is well above the prior art of 2%. For all the ethylene they produced, the solar energy conversion efficiency was about 4%, about the same rate as photosynthesis.

Conversion process turns carbon dioxide into cash

Aditya Prajapati et al, CO2-free high-purity ethylene from electroreduction of CO2 with 4% solar-to-ethylene and 10% solar-to-carbon efficiency, Cell Reports Physical Science (2022). DOI: 10.1016/j.xcrp.2022.101053

Provided by the University of Illinois at Chicago

Citation: A Breakthrough Discovery in Carbon Capture Conversion for Ethylene Production (2022 September 9) Retrieved September 10, 2022 from https://phys.org/news/2022-09-breakthrough-discovery-carbon-capture-conversion .html

This document is protected by copyright. Except for fair trade for the purpose of private study or research, no part may be reproduced without written permission. The content is for informational purposes only.

#breakthrough #discovery #converting #CO2 #capture #ethylene #production

Leave a Comment