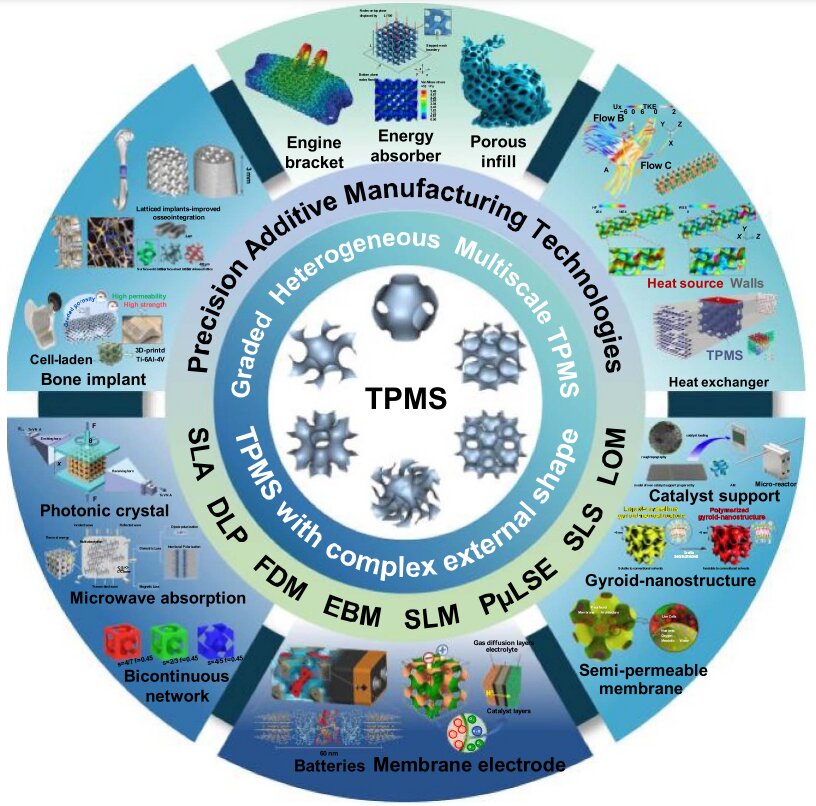

Overview of this overview of porous TPMS structures. Photo Credit: By Jiawei Feng, Jianzhong Fu, Xinhua Yao, Yong He.

With the rapid development of material science and manufacturing science, a large number of complex structures have been designed, manufactured and applied in the industrial field.

Most current industrial applications belong to solid structures without holes. Some internal holes are even considered structural manufacturing defects. However, in nature there are a large number of complicated porous structures, such as skeletons, honeycombs, corals, sponges and cork. The particular properties of natural porous structures attract researchers to try to design various biomimetic porous structures. Biomimetic porous structures, represented by honeycombs, foams, and lattices, have achieved excellent application results in previous studies.

In recent years, more and more researchers have attempted to use TPMS to design and fabricate porous structures. TPMS is a periodically smooth implicit surface with zero mean curvature. Compared with other types of porous structures, the TPMS porous structure has two obvious advantages: (1) The entire TPMS porous structure can be accurately described by mathematical expressions. The fundamental properties like porosity and volume specific surface area can be directly controlled by the function expression parameters; (2) The surface of TPMS is very smooth. There are no sharp curves or connection points of the porous lattice structure. And the overall structure is highly networked. Structures very similar to TPMS have been found in some biological tissues in nature.

At present, research on the porous structure of TPMS is flourishing, but there are still many problems to be solved in the key steps of design, manufacture and application.

Recently, postdoctoral fellow Feng Jiawei, Professor Fu Jianzhong, Associate Professor Yao Xinhua, and Professor He Yong from Zhejiang University School of Mechanical Engineering published “Triply Periodic Minimal Surface (TPMS) Porous Structures: From Multi-Scale Design, Precision Additive Manufacturing to Multidisciplinary Applications” in International Journal of Extreme Manufacturingwhich systematically summarized the research progress of the last years on triply periodic minimal porous surface structures.

The article summarized the current geometric design algorithms and power control strategies for porous TPMS structures. Based on this, various additive precision manufacturing processes for the production of porous TPMS structures were discussed. The performance advantages of the porous TPMS structure and the wide application prospects in the future were also demonstrated.

Most of the natural porous structures have uneven and irregular pores. Based on the implicit surface features of TPMS, by controlling the distribution of periodic parameters and curvature parameters, biomimetic structures resembling natural porous structures can be generated.

Regarding internal pores, a variety of non-uniform (gradient), non-homogeneous, multi-scale TPMS design algorithms for porous structures have been proposed. Regarding the shape of the porous structures, the porous TPMS structure with free surface shape can be generated by combining different calculation geometry algorithms.

Performance analysis of the porous TPMS structure has been a research focus in recent years. From the perspective of different disciplines, researchers have analyzed the multidisciplinary application performance of the porous TPMS structure such as mechanical, thermal and acoustic.

Compared with the traditional topological porous structure, TPMS has unique advantages. The smooth geometry has a significant impact on the actual increase in performance. Starting from the structural properties, a large amount of current research focuses on how the structural properties of TPMS can be further optimized and improved to meet the increasingly complex requirements of industrial application.

Additive manufacturing technology is an ideal solution for manufacturing intricate porous TPMS structures. Various processes have been attempted to fabricate porous TPMS structures including Selective Laser Melting (SLM), Selective Laser Sintering (SLS), Stereolithography Device (SLA), Digital Light Processing (DLP), Fused Deposition Modeling (FDM), etc.

Various types of high-precision porous TPMS structures can be produced by selecting appropriate materials and processing techniques. However, in the process of trajectory planning, there is still a lack of efficient and accurate process planning methods for porous TPMS structures. And there is still a lot of room for improvement in terms of manufacturing quality.

With continuous improvement in design and manufacturing levels combined with excellent structural properties, porous TPMS structures have been successfully used in many disciplines. The internal pores of TPMS can intrude into the platform stage under compressive load to continuously absorb energy.

At present, there are a large number of reports on the application of porous structure TPMS energy buffering devices. The smooth pores of TPMS are very suitable for cell adsorption and growth. And pores are more suitable for nutrients and nutrients.

At present, research on the design, fabrication and application of porous TPMS structures is still a hot topic. Researchers have conducted a number of interesting experiments centered around the uniqueness of the porous TPMS structure. But there are still many issues that require further discussion and research.

Current research on the design, fabrication, and application of porous TPMS structures is relatively isolated. To ensure good manufacturing quality, some manufacturing process aspects should be added as constraints to the design process to improve manufacturability of porous TPMS structures. Most of the TPMS porous structures currently used in practical applications are uniform porous structures with regular pore distribution.

In the future, the mechanism of influence of the pore distribution on the actual performance should be further explored to further optimize and improve the performance of porous TPMS structures. Especially in the complex environment of industrial applications, the implementation of multi-physical performance analysis and multi-disciplinary application performance combination optimization of porous TPMS structure is an important basis for promoting the wider application of porous TPMS structure.

The research links the porous structure of silicon and its ability to ‘capture’ incoming light.

Jiawei Feng et al., Triple periodic minimal surface (TPMS) porous structures: from multiscale design, precision additive manufacturing to multidisciplinary applications, International Journal of Extreme Manufacturing (2022). DOI: 10.1088/2631-7990/ac5be6

Provided by the International Journal of Extreme Manufacturing

Citation: TPMS Porous Structures: From Multi-Scale Design and Precision Additive Manufacturing to Multidisciplinary Applications (2022, September 15), retrieved September 17, 2022 from https://phys.org/news/2022-09-tpms-porous- multi-scale precise additive.html

This document is protected by copyright. Except for fair trade for the purpose of private study or research, no part may be reproduced without written permission. The content is for informational purposes only.

#Porous #TPMS #Structures #Multiscale #Design #Precision #Additive #Manufacturing #Multidisciplinary #Applications

Leave a Comment