Graphene is a suitable active ingredient for electric double layer supercapacitors (EDLCs) due to its high electrical conductivity and lightweight composition. However, a porous configuration is required to maximize the specific energy density of graphene for many novel energy storage applications.

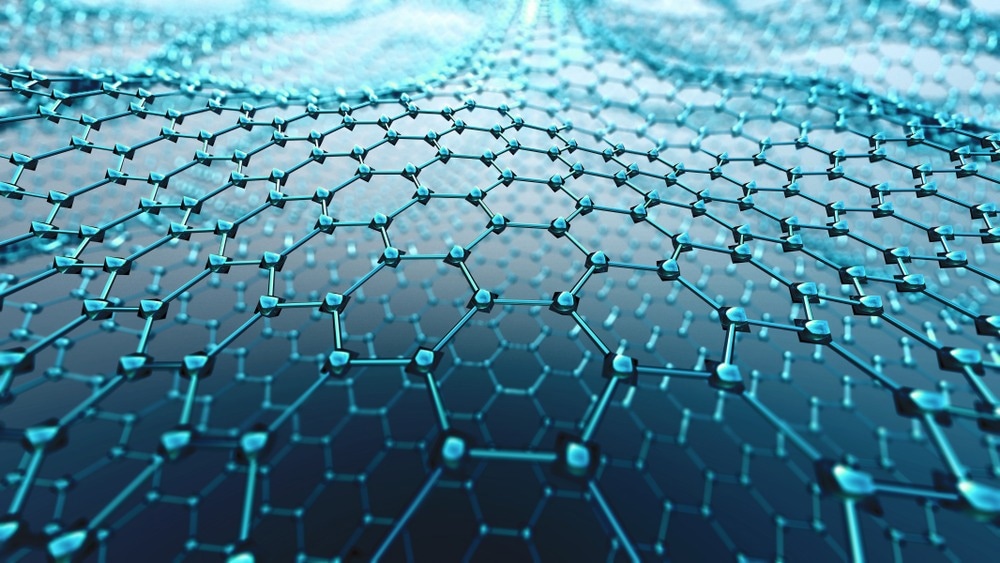

Study: Soft Template-Assisted Fabrication of Mesoporous Graphenes for High-Performance Energy Storage Systems. Credit: Neon_dust/Shutterstock.com

A recent study published in the journal ACS Applied Materials & Interfaces proposes a simple strategy to fabricate mesoporous graphene with applications in high-performance energy storage systems such as electric double-layer supercapacitors (EDLCs).

Electric Double Layer Capacitors (EDLCs): Overview and Challenges

Energy storage systems have recently gained traction due to the urgent need to use fossil fuels in many industrial sectors such as B. the transport sector, experienced a lot of attention. In this context, electric double layer capacitors (EDLCs) are important energy storage systems due to their high energy density and exceptional cycle stability.

However, due to the insufficient specific contact area, conventional energy storage systems made of activated carbon (AC) have a poor power density, which leads to an insufficient formation of an electrical double layer between the electrode material and the electrolyte.

Therefore, a drug with a high specific contact area needs to be developed to achieve high energy densities and meet the requirements of novel energy storage systems.

Previous studies have attempted to create high surface area carbon-based compounds such as B. highly porous structured carbons, for energy storage purposes. However, traditional carbon-based materials have low conductivity, resulting in low power density and poor cyclic stability.

Mesoporous graphene for energy storage applications

Graphene is considered a potential carbonaceous material because of its remarkable electrical conductivity. However, the high van der Waals contact between the graphene layers makes stacking inevitable, resulting in a limited available surface area.

This inherent disadvantage of graphene can be overcome by adding a three-dimensional (3D) porous microstructure that increases the available surface area while maintaining beneficial electrical properties.

The resulting material, known as mesoporous graphene, combines the advantages of graphene, ultrathin 2D morphology, and mesoporous structures, and significantly improves the power and energy densities of energy storage devices such as electric double layer capacitors (EDLCs).

Several research groups have attempted to synthesize 3D mesoporous graphene using a catalytic template-assisted technique. However, due to a volatile catalytic template, the pore diameter and contact area were quite large. Therefore, the development of an efficient technique to synthesize 3D mesoporous graphene with a large contact area for high-energy-density EDLCs remains a major challenge.

What did the researchers do in this study?

In this study, researchers created 3D mesoporous graphene by using block copolymers (BCPs) to construct the mesostructured active template and carbon resource. An amphiphilic poly(styrene) block poly(2-vinylpyridine) copolymer (PS-b-P2VP) was swollen in heated ethanol and then dehydrated to generate a mesostructured template.

Electroless plating generated the reactive template by selectively depositing a nickel precursor as a graphene catalyst on the P2VP layer.

Interestingly, the highly porous architecture of mesoporous graphene was successfully preserved during catalytic decomposition even at high temperatures, as the mechanical toughness of the PS-b-P2VP composite is sufficient to act as a rigid reinforcement and prevent aggregation of the nickel catalyst.

The surface of the mesoporous graphene produced in this way was examined using state-of-the-art techniques such as transmission electron microscopy (TEM), X-ray diffraction (XRD) and scanning electron microscopy (SEM). The Barrett-Joyner-Halenda (BJH) technique was used to calculate the pore size distribution in mesoporous graphene particles from the adsorption and desorption branches.

Important highlights of the research

The mesostructured templates properly maintained their architectures without structural failure upon high-temperature catalytic decomposition, enabling the synthesis of mesoporous graphene with a pore diameter of 3.5 nanometers. The mesoporous graphene thus prepared had a bicontinuous shape, with the graphene assembling into 3D mesopores with a large contact area.

The large specific contact area and small pore diameter enabled a significant number of electrolytes to penetrate mesoporous graphene. Furthermore, the electrically conductive pathways in the mesoporous graphene sheets resulted in highly efficient electron transfer at the interface.

When mesoporous graphene and ionic liquids were used as electrode material and electrolyte, the resulting EDLC showed high-voltage performance and remarkable energy storage efficiency, including high specific capacity, high power density, and good cyclic stability.

These results suggest that mesoporous graphene could be a promising carbon material for fabricating high-performance electrolytic energy storage systems.

Relation

Kim, K.-W. et al. (2022). Soft-templating fabrication of mesoporous graphenes for high-performance energy storage systems. ACS Applied Materials and Interfaces. Available at: https://pubs.acs.org/doi/10.1021/acsami.2c12948

Disclaimer: The views expressed herein are those of the author, expressed in his own capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork, the owner and operator of this site. This disclaimer is part of the terms of use of this website.

#Simple #method #fabricate #mesoporous #graphene #energy #storage #systems

Leave a Comment