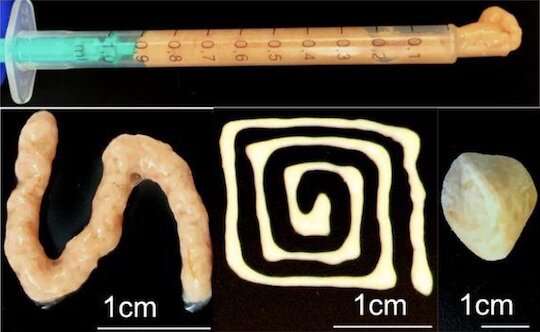

Rice University life scientists have turned bacteria into self-assembling building blocks. The macroscale, slimy artificial living materials they make up could be used to soak up environmental pollutants or as custom catalysts. Credit: Jeff Fitlow/Rice University

Engineered living materials promise to support human health, energy and environmental cleanup efforts. Now they can be built large and customized with less effort.

Rice University life scientists have introduced inch-sized, slimy colonies of man-made bacteria that self-assemble from the bottom up. They can be programmed to absorb pollutants from the environment or to catalyze biological reactions, among many potential applications.

The creation of autonomously engineered living materials—or ELMs—was a long-time goal of life scientist Caroline Ajo-Franklin before she joined Rice in 2019.

“We make material from bacteria that acts like putty,” said Ajo-Franklin. “One of the nice things about it is how easy it is to make, it just takes a little exercise, some nutrients and some bacteria.”

A study published this week in nature communication describes the development of flexible, adaptable ELMs by the laboratory using Caulobacter crescentus as the biological building block. While the bacteria themselves can easily be genetically modified for various processes, designing them to self-assemble has been a long and complicated process.

It involved manipulating the bacteria to represent and secrete the biopolymer matrix that gives the material its shape. C. crescentus already expresses a protein that covers its outer membrane like scales on a snake. The researchers modified the bacteria to express a version of this protein, which they call BUD (for bottom-up de novo, like from scratch), with properties not only relevant to the formation of ELMs (called BUD-ELMs) are cheap, but also provide tags for future functionalization.

We wanted to prove that it is possible to grow materials from cells, like a tree grows from a seed,” said Sara Molinari, a postdoctoral researcher in Ajo-Franklin’s lab and lead author of the study. “The transformative aspect of ELMs is that they contain living cells that allow the material to self-assemble and repair in the event of damage. In addition, they can be further developed to perform non-native functions such as B. the dynamic processing of external stimuli.”

Molinari, who earned her PhD with Rice in bioscientist Matthew Bennett’s lab, said BUD-ELM is the most adaptable example of an autonomously formed, macroscopic ELM. “It shows a unique combination of high performance and sustainability,” she said. “Thanks to its modular nature, it could serve as a platform to create many different materials.”

According to the researchers, ELMs grow in a bottle in about 24 hours. First, a thin skin forms at the air-water interface, impregnating the material. Constant shaking of the flask promotes growth of the ELM. Once it expands to a sufficient size, the material sinks to the bottom and stops growing.

“We found that the shaking process affects how large the material we get,” said co-author and graduate student Robert Tesoriero Jr. “In part, we’re looking for the optimal range of material that we can get in a flask of about 250 millimeters can get . It is currently about the size of a fingernail.”

“Getting to the centimeter scale with a sub-micron cell means they organize together over four orders of magnitude, about 10,000 times larger than a single cell,” Molinari added.

Their functional materials are robust enough to survive in a jar on the shelf for three weeks at room temperature, which means they can be transported without refrigeration.

Engineered living materials developed at Rice University can be adapted for a variety of applications, including environmental remediation or as custom catalysts. Credit: Sara Molinari/Ajo-Franklin Research Group

The lab proved that the BUD-ELM could successfully remove cadmium from a solution and perform biological catalysis by enzymatically reducing an electron carrier to oxidize glucose.

Since BUD-ELMs carry tags for attachment, Ajo-Franklin says it should be relatively easy to modify them for optical, electrical, mechanical, thermal, transport, and catalytic applications.

“There’s a lot of room to play around, which I think is the fun part,” Tesoriero said.

“The other big question is that while we love Caulobacter crescentus, it’s not the most popular kid on the block,” Ajo-Franklin said. “Most people have never heard of it. So we’re really interested in knowing if these rules that we discovered in Caulobacter can be applied to other bacteria.”

She said ELMs could be particularly useful for environmental remediation in resource-poor settings. C. crescentus is ideal for this because it requires fewer nutrients to grow than many bacteria.

“One of my dreams is to use the material to remove heavy metals from water and then when it reaches the end of its life, to subtract a small portion and grow it on the spot into fresh material,” said Ajo- Franklin. “That we could do it with minimal resources is really a compelling idea to me.”

The work is co-authored by graduate student Swetha Sridhar, postdoctoral fellow Rong Cai and lab supervisor Jayashree Soman from Rice, Kathleen Ryan from the University of California, Berkeley, and Dong Li and Paul Ashby from Lawrence Berkeley National Laboratory, Berkeley, California. Ajo-Franklin is Professor of Biological Sciences and CPRIT Fellow in Cancer Research.

Technical living “scaffolding” for building materials

Sara Molinari et al, A de novo matrix for macroscopic bacterial living materials, nature communication (2022). DOI: 10.1038/s41467-022-33191-2

Provided by Rice University

Citation: Lab grows macroscale, modular materials frombacter (2022, September 22), retrieved September 23, 2022 from https://phys.org/news/2022-09-lab-macroscale-modular-materials-bacteria.html

This document is protected by copyright. Except for fair trade for the purpose of private study or research, no part may be reproduced without written permission. The content is for informational purposes only.

#Lab #grows #macroscopic #modular #materials #bacteria

Leave a Comment