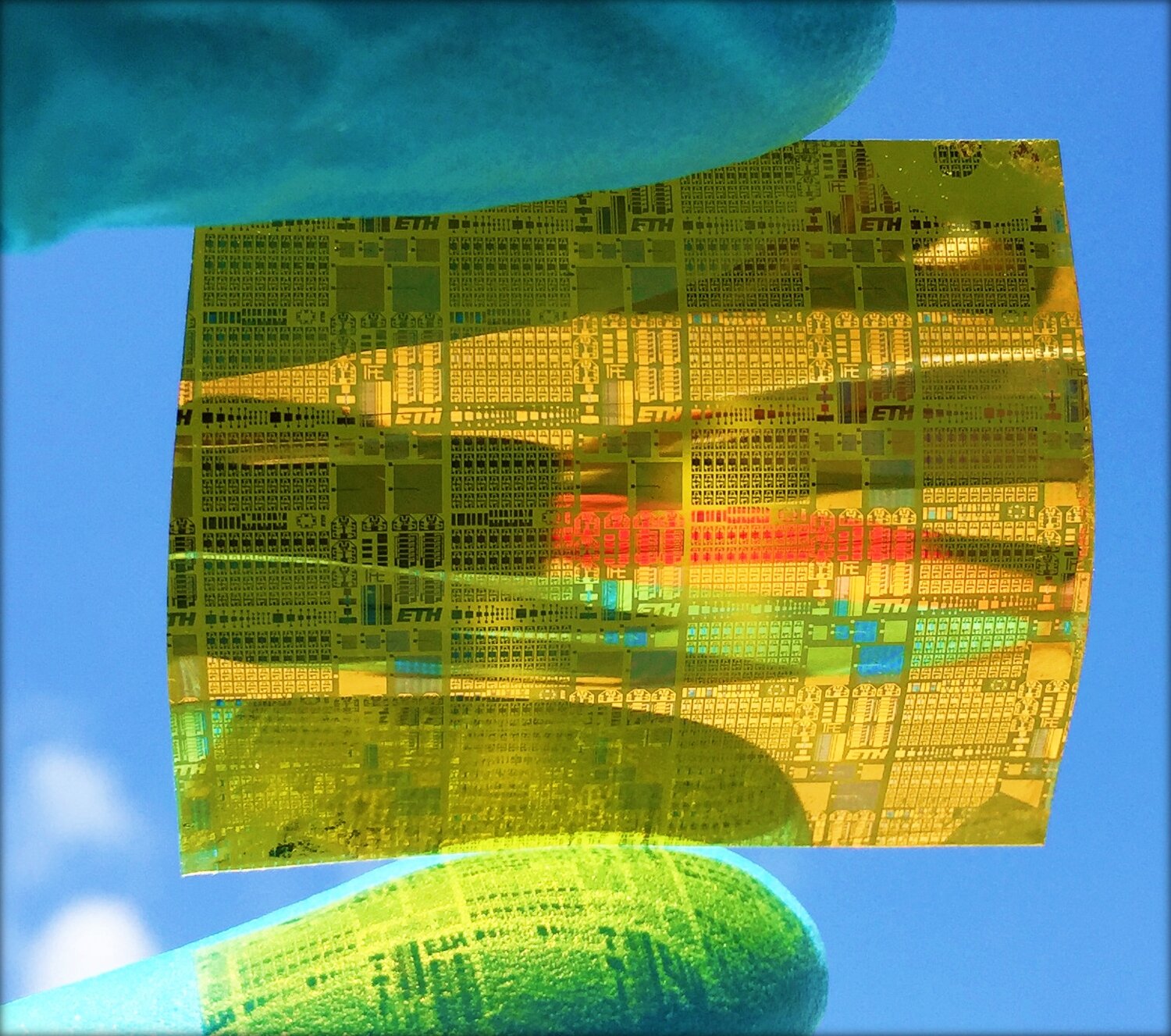

Flexible: Electronic circuits on a polyimide film from the Empa laboratory form synaptic transistors. Photo credit: Empa

As part of the Functional Oxides Printed on Polymers and Paper (FOXIP) project, researchers from Empa, EPFL and the Paul Scherrer Institute tried to print thin-film transistors with metal oxides on heat-sensitive materials such as paper or PET. Ultimately, the goal was not achieved, but those involved see the project as a success – because of a new printing ink and a transistor with a “memory effect”.

The bar was undoubtedly high: the aim was to print thin-film transistors on paper substrates or PET films. Electronic circuits with such elements play an important role in the growing Internet of Things (IoT), for example as sensors on documents, bottles, packaging – a global market worth billions.

If it were possible to produce such transistors with inorganic metal oxides, this would open up a wealth of new possibilities. Compared to organic materials such as the semiconducting polymer polythiophene, explains project leader Yaroslav Romanyuk from Empa’s Laboratory for Thin Films and Photovoltaics, the electrons in these materials are much more mobile. They could therefore significantly increase the performance of such elements and would not have to be protected from air and moisture by expensive encapsulation.

heat as a challenge

There is a problem with inks that contain metal oxides: in order to form a stable transistor, the materials must be sintered after printing – typically in an oven. Alternatively, drying and sintering can be carried out with light, for example with low-wave UV radiation or a xenon lamp. The printed layer is heated with very short flashes of light to protect the substrate. Water, solvents and binders leave the material.

However, such processes heat the substrate up to 200 degrees – far too hot for paper or PET, which loses strength at temperatures around 80 degrees, while other plastics such as polyimides can withstand much higher temperatures.

From 2017 to 2021, experts from Empa, the Soft Transducers Laboratory of EPFL and the Polymer Nanotechnology Group at the Paul Scherrer Institute (PSI) worked in a project initiated by the ETH Board in the “Strategic Focus Area – Advanced Manufacturing” (SFA-AM). at every step of the process – for example, coatings to smooth the surface of paper, ink formulations, irradiation, etc. – and made quite some progress.

But their “ultimate wish”, as Romanyuk puts it, to print functional thin-film transistors on paper, was not fulfilled. The process temperatures were still too high and the material too rough. And finally, the printed transistors on polymer foils had too little electrical output.

Expect the unexpected

Disappointed? No, says Jakob Heier from Empa’s Functional Polymers department. “The project was by no means a failure.” Not only because of new insights into technical details, but because of unexpected “side effects”.

“It was a very exciting project with many surprises,” Heier recalls of an incident that was to have consequences. This was the material graphene, conductive carbon in layers as thin as atoms, which is also well suited for printed transistors on flexible foils.

A graduate student on the team would not be happy that graphene inks could not be printed at higher concentrations. The particles aggregate, they clump together, so a thin film cannot form. Instead of using just one solvent, the researcher tried a special emulsion of graphene and three solvents. But this coating also failed in the first attempt. However, when the ink was evenly mixed and then subjected to slight shearing forces on the next attempt, the print succeeded.

Curious, the experts examined the phenomenon and found that the shear forces fundamentally change the structure of the ink. The fine graphene peels off in the liquid, allowing van der Waals forces to take effect. These are relatively weak forces of attraction between atoms or molecules. The result was a gel-like ink – without binding agents such as polymers, which otherwise ensure that the liquid retains its consistency and does not separate.

A process with market potential

The researchers implemented a solution with practical benefits that also works at room temperature: the ink dries without heating. As it turned out, such van der Waals inks can be made not only with graphene, but also with other two-dimensional materials for printing. The process has since been patented, and experts say some companies are already showing interest in making the coveted inks — all by chance, which the team investigated with healthy curiosity.

It wasn’t the only surprise in the FOXIP project, as Yaroslav Romanyuk tells. A field effect transistor with an insulating layer of aluminum oxide printed on a heat-resistant polyimide plastic showed quite strange behavior. Instead of a constant signal, as might have been expected, it showed rising waves. The output signal became stronger because it “remembered” previous incoming signals.

“Showing such a ‘memory’ effect is actually undesirable for a transistor,” explains Romanyuk.

But another student on the team had an idea to use the phenomenon in a different way. A transistor with such a memory effect works in a similar way to circuits in the human brain. Synapses between nerve cells not only transmit signals, but also store them. Such a synaptic transistor could therefore be extremely interesting for computers that are modeled on the human brain. But what could it do?

With the support of Mozart

To explore its potential, the team built an electronic copy of the human auditory process along with the thin film transistor – and fed it a popular Mozart melody: Rondo “Alla Turca” from Sonata No. 11 in A major.

“It had to be a lively piece,” says Romanyuk with a smile. This experiment and further analysis showed that the transistor’s synaptic function is preserved from a few Hertz to almost 50,000 Hertz – a much higher bandwidth than comparable printed transistors.

Concrete applications for this basic research – which the team has published in the online journal – are of course not yet in sight Scientific Reports– in contrast to printing inks without binders. But on the way to new computer technologies, the findings can be a useful and surprising step – as so often in the history of science.

Such coincidences are the icing on the cake for Romanyuk and many other researchers, especially in projects that push the limits of what is feasible.

“We deliberately set our goals very high,” he says. “Coincidences play a very important role. You face a big challenge and then suddenly and unexpectedly these coincidences happen.”

Manufacture of high power printed thin film transistors that can operate at one volt

Foxip project page: www.sfa-am.ch/foxip.html

Provided by the Federal Materials Testing and Research Institute

Citation: Researchers Try to Print Thin Film Transistors Using Metal Oxides on Heat-Sensitive Materials (2022 September 15) Retrieved September 16, 2022 from https://phys.org/news/2022-09-thin-film-transistors-metal- oxides-heat-sensitive.html

This document is protected by copyright. Except for fair trade for the purpose of private study or research, no part may be reproduced without written permission. The content is for informational purposes only.

#Researchers #attempting #print #thinfilm #transistors #metal #oxides #heatsensitive #materials

Leave a Comment