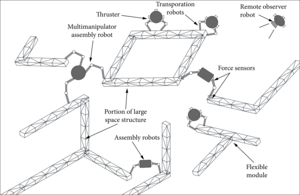

Image: Heterogeneous space robots assemble large space structures in orbit.

outlook more

Credit: Outer Space: Science & Technology

The construction of large structures is one of the main development trends of space exploration in the future, such as B. large space stations, large space solar power plants and large space telescopes. However, due to their size, such structures cannot be directly carried into space by rockets or spacecraft. As such, these large structures must be broken down into multiple modular units that are launched into space by a launch vehicle and then assembled. This is an important task of On-Orbit Servicing (OOS): On-Orbit Assembly. It is an important development trend aimed at making full use of space robots to autonomously assemble space structures in the aerospace industry. In a recent review in Space: Science & TechnologyQirong Tang from Tongji University and Delun Li and other experts and engineers from the China Academy of Space Technology summarized the development status of space robot technology and relevant space robot assembly technology over the past few decades.

First, the author presented the current state of research on on-orbit assembly of space robots. The aerospace industry has researched and practiced in-orbit service technology for decades. It was known that the space assembly task could be done in orbit by space robots and astronauts in cooperation. Although manual assembly by astronauts had proven to be an effective method of building space structures, this method had many limitations. Therefore, it was very necessary to use space robots to autonomously complete assembly tasks in orbit. In general, space on-orbit assembly technology has gradually evolved from manual to autonomous work. The way of working has shifted from simple assisted astronaut operations to autonomous assembly and maintenance. Mission scenes have also changed from a single small object to a large spatial structure. However, in terms of the development of space-in-orbit assembly technology, it has not yet matured and been applied. However, as for the development of space assembly technology in orbit, it had not yet been matured and applied. As the size of the object becomes larger, the flexible vibration becomes stronger, and the assembly accuracy during the assembly process becomes higher, research on the cooperation of multiple robots to complete high-precision operation needs to be deepened.

The author then discusses the key technologies of space-to-orbit assembly, including assembly sequence planning, space robot movement planning, on-orbit assembly, and methods for vibration suppression and compliance control. First, the development of planning algorithms for space robots was introduced on the basis of the movement planning of space robots and the assembly process planning. Planning assembly sequences described the details of assembly operations, how different parts should be placed in a product. The traditional assembly planning method has been greatly influenced by human factors. At the same time, the increasing complexity of the assembly structure and the diversification of the assembly evaluation criteria also brought difficulties in assembly scheduling. Computer-intelligent assembly methods such as virtual reality technology could make up for this deficiency and improve the efficiency and reliability of assembly sequencing. As for movement planning, it was of great importance for the orbital operations of space robots. When a space robot performs assembly in space in orbit, a basic task was to move the spacecraft from one point to another in state space. For the spacecraft itself, its state space was the translation and rotation of the spacecraft in the Cartesian coordinate system. Therefore, the traditional Dijkstra, A* and other algorithms can be used as path planning methods. In addition, commonly used intelligent bionic algorithms have also been applied, including genetic algorithms, ant colony algorithms, and particle swarm algorithms. Second, the assembly procedure for space robots has been summarized. The artificial potential field method, the machine vision method, the neural network learning method, etc. have been developed and applied to important scenarios, i.e. assembling the large space vehicle and performing space multi-robot multi-tasking. Finally, from the control point of view, how to solve the vibration suppression and compliant mounting of the on-orbit mounting is reviewed. Because of the microgravity conditions in space, it was easy to make large structures vibrate. Analysis of single and multi-robot assembly strategies as well as branch and bound hybrid method and improved ant colony algorithm could suppress the vibration disturbance. In the assembly contact process, there was direct contact between the targets, and some force (moment) was generated, so compliance control was also very necessary. Current compliance control methods are mainly divided into two categories: active compliance and passive compliance. Passive compliance was entirely dependent on the properties of the material, was uncontrollable, and had high uncertainty. And active compliance referred to obtaining contact force information through sensors, using the information as feedback input to the controller, and performing feedback control of the robotic arm to reduce the contact force and achieve the purpose of compliance control. Active force-position control has generally inherited traditional “force-position” hybrid control, impedance control, and other methods.

Then, to simulate the space assembly scene on the ground, the author introduced the development of ground verification experiments and provided ideas for the effective verification of space assembly technology in orbit. Due to the high cost of constructing orbiting space, the space manipulator and related control system and other environments on the ground need to be checked to ensure that all equipment can function normally before assembling in orbiting space. The biggest difference between ground and space was whether there was gravity, so simulating zero microgravity conditions was the key and focus of ground test verification. Currently, there are five commonly used bottom testing methods, namely, the air float method, the water float method, the force compensation method, the parabolic method, and the free fall method. The space administrations or space institutes of various countries had set up corresponding laboratories, in particular the air flotation experiment platform and the gravitational compensation experiment platform, with the aim of completing the “space-ground consistency” experiment on the ground and ensuring the accuracy and feasibility of the experiment.

Finally, the author summarized opportunities and challenges of on-orbit assembly in the future.

The assembly in orbit relies on the coordination of space multi-robots and a super presence, and supporting intelligent interaction skills such as brain control, voice control and eye control is worth developing.

Smarter on-orbit assembly technology is increasing, including autonomous decision-making capabilities, fault diagnosis and self-repair capabilities, autonomous mission planning, autonomous work, and learning capabilities.

Diversified capabilities of space robots are potential. The robots must not only have long-distance transfer and movement capabilities, but also be able to perform high-precision operations and flexible operations, including pinching, rotating, pulling, cutting, connecting operations, and even own functions of the robot group reconstruction, robot task reconstruction and configuration reconstruction.

diary

Space Science and Technology

article title

An overview of space robotics technologies for on-orbit assembly

Article publication date

September 1, 2022

Disclaimer: AAAS and EurekAlert! are not responsible for the accuracy of the press releases published on EurekAlert! by contributing institutions or for the use of information about the EurekAlert system.

#scientist #summarize #development #space #robotic #technologies #onorbit #assembly

Leave a Comment